- This is the flagship of SIMA, the bucket are a number of studies for its continuous improvement, one of the more recent introduction of the curved side for easy loading and processing operators

- Sima mixing buckets are applicable to any type of skid-loader, backhoe, wheel loader, telescopic lift, excavator or tractor (with front loader), all equipped with Danfoss hydraulic motor, Hardox 5 front grille mixing material Hot galvanized with bag breaks, electrode diverter to operate the exhaust nozzle, hydraulic hoses and electrical connection to apply it to the operating machine, exhaust pipe.

Concrete mixing bucket SIMA

Optional:

- Hydraulic opening grill with safety value

- Pneumatic opening grille with safety valve

- Double Hardox 450 Hard Case Base

- Sima System multi-connection system

- Side Drainage Trap

- Pressure accumulator

Mode utilization Bucket

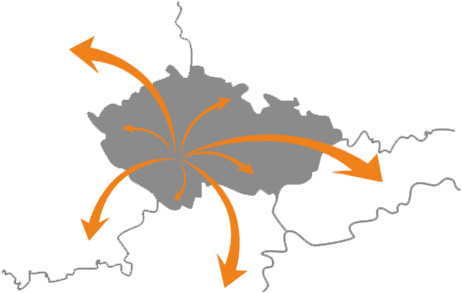

WEARING THE CONCRETE EVERYWHERE

Once applied to the machine, the mixing bucket allows you to carry anywhere concrete.

AVOID THE SEPARATION OF COMPONENTS

The impellers of the mixing bucket continue to rotate during transportation maintaining the mixture in the best condition.

NEED FOR A LOW COST INSTALLATION

The use of the new mixing bucket will only result in a small integrated in the hydraulic system of your car, thus leaving unchanged its payload.

Shortens PERFORMANCE OF CONCRETE

Thanks to the particular mechanism of the grinding wheel, it takes 3 minutes to mix the best elements, even for the mixing buckets larger (1,000 liters in 3 min.).

USE YOUR EQUIPMENT MAINTENANCE QUICK AND EASY

It can be applied to any type of machine, increasing the possibility of use.

DOWNLOAD ALSO SET TO HIGH

Take advantage of the lifting capacity of the machine where the mixing bucket is applied.

Phases Processing Concrete

Phase 1: Charge

The Charge of the inert material is made directly with the mixing bucket attached to the machine working. In the second stage are then added water and the cement in the proportions necessary to work.

Time of operation: 30 seconds.

Accessories: Grid hydraulic opening.

Phase 2: Mixing

The particular design of the impellers, pushes the mixture towards the center of the bucket. In this way we obtain concrete of better quality due to this forced mixing (and not through fall from the walls).

Time of the transaction: 2 minutes.

Phase 3: Exhaust

The mixing bucket is equipped with opening in the bottom that allows the drain to the fall of the product in process.Through the application of a discharge hopper, it is possible to direct the concrete at the desired point.

Time of the transaction: 2 minutes.

Technické parametry:

| S10 | S15 | S20 | S25 | S30 | S35 | S40 | S45 | S50 | S75 | |||

| Capacity por |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

750 |

1000 |

|

| Machine weight kg |

182 |

265 |

280 |

350 |

380 |

400 |

540 |

600 |

700 |

950 |

1000 |

|

|

Weight of concrete* |

240 |

360 |

480 |

600 |

720 |

840 |

960 |

1080 |

1200 |

1800 |

2400 |

|

|

Weight at full load kg ** |

422 |

625 |

760 |

950 |

1100 |

1240 |

1500 |

1680 |

1900 |

2750 |

3400 |

|

|

Transmission type |

adapter |

adapter |

chain |

chain |

chain |

chain |

chain |

chain |

chain |

chain |

chain |

|

|

Recommended steps |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

|

| Transmission ratio |

1 / 8.4 |

1 / 8.4 |

1 / 8.4 |

10/54 |

10/54 |

10/54 |

9/46 |

9/46 |

9/46 |

10/65 |

10/65 |

|

|

Oil flow l min./max |

41/75 |

41/75 |

41/75 |

41/75 |

41/75 |

52/90 |

65/90 |

69/150 |

69/150 |

126/240 |

126/240 |

|

| Continuous pressure series |

130 |

130 |

130 |

140 |

140 |

180 |

160 |

160 |

160 |

180 |

160 |

|

| Bar peak pressure |

180 |

180 |

180 |

180 |

180 |

210 |

190 |

190 |

190 |

200 |

190 |

|

|

Opening of the central exhaust |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

hydraulics |

|

| Dimensions |

100x70x65 |

100x85x70 |

125x85x70 |

155x90x75 |

165X90X75 |

170x100x75 |

165x105x100 |

175x105x105 |

195x105x105 |

195x125x120 |

210x130x130 |